In this article we are going to compare galvanized steel vs stainless steel. We will include the following:

How we at Prototype Finder can help you

What is galvanized steel

What is stainless steel

Their advantages

The differences between the two

Products produced with these materials

Which is better for your next product

First, let us see how we here at Prototype Finder can help.

We at Prototype Finder are a manufacturing company. We specialize in both prototype development and production. But we also work with CNC machining and injection molding as core specialties. We have worked with both stainless steel and galvanized steel for many years. Are you in need of help for your next project? Do you need help to determine what steel or material is best for your next application? Don’t hesitate to request a quote or contact us and we can help in any way we can.

So what is galvanized steel? Galvanized steel is steel which is coated with a layer of zinc. The main reason for this is that zinc protects the steel itself from rusting. Often against the combination of moisture and oxygen. Being exposed to the elements, also known as weathering can cause the steel to rust faster. Rust eats away at the steel and reduces its integrity, making it a safety concern. So many steel pieces, such as nuts, bolts and screws are galvanized to help slow down this process. To galvanize a piece of steel helps against water, granted it’s not salt water. Can galvanized steel be welded? Yes. Even welders can work with galvanized steel. But they need extra protection when doing so. To avoid breathing in any harmful fumes during the welding process.

Galvanized steel is steel that we coat in zinc. Used for its rust-protecting properties.

Since we have already covered galvanized steel, what is stainless steel? Stainless steel is a combination of iron, carbon and chromium. We use this steel because it offers significant corrosion resistance. It is not coated in a substance, like zinc coats onto steel to become galvanized. But by mixing elements together to make stainless steel it has its properties built into it. Different combinations result in different resistance. Because stainless steel is a mixture of materials. Both from corrosion and damage. Useful for high, constant exposure to caustic chemicals or when exposed to sea water. Compared to galvanized steel, stainless is often the more expensive of the two. But this we balance this with the fact that it is also generally stronger too.

Stainless steel is steel that we mix with chromium. Chosen for its significant corrosion and rust resistance.

There are many advantages to galvanized steel. Let’s take a look at some of these below:

Lower Costs – When it comes to other coating methods, galvanizing offers a host of benefits. Being a somewhat simple process, affordable and fast. By galvanizing metal you can complete this process fast. Then move onto the next production process. Lowering general costs. Also this metal requires lower maintenance which also translates to lower costs.

Low Maintenance – Galvanized metal is very easy to clean. Often it’s as simple as spraying it with water. It also requires very minimal re-coating, hardly any at all. Added to this is the durability of this metal. Resistant to abrasion and great at absorbing impact. Again resulting in less time to maintain. Also to repair and keep production times running as easy as possible.

Long Life – A huge factor for galvanized steel is its longevity. Under very high weather exposure it can last up to 20 years. But under normal circumstances it can live up to 100 years! Water is one of the core enemies of steel, as it causes rusting. By coating it in zinc, it increases its lifespan and becomes more reliable and durable.

Quick Application – To galvanize steel takes only minutes. Not only this but it provides a full protective coating to the entire piece.

Ease of Inspection – Galvanized steel doesn’t need any kind of complicated machinery. You can assess galvanized coatings by eye. Combined with non-destructive thickness testing. If it looks like it is in good condition then there is nothing hidden beneath the surface, it is good!

Tough Coating – The galvanized coating is tough. It helps to protect the structure. But also give outstanding resistance to any mechanical damage. During transport, erection and service.

Galvanized steel is a great choice if you are looking for a low-cost, low-maintenance steel. With a long lifespan and ease of application and inspection.

Let’s take a look at the many advantages of using stainless steel below:

Cleanliness – One of the biggest benefits of stainless steel is how hygienic it is. The surface itself is easy to clean and sanitize. But not only this, the material itself is smooth and non-porous. Meaning dirt, grime and bacteria cannot hide in its cracks and crevices. Any dirt is only wiped away. Because of this hygienic factor, it is a great choice in both the medical and cooking industries.

Recyclable – Stainless steel is recyclable. 100% of it. Also over 50% of all stainless steel comes from recycled previously-used stainless steel.

Corrosion Resistant – Famous for being resistant against corrosion. When created in 1913 it received the label as “rust-less steel”. It is also strong against rust, acids, alkaline and water stains, among others. We can even add other elements to increase its corrosion-resistant properties. Like nickel, titanium and molybdenum.

Aesthetic – Superficial, but no less important is the appearance of this metal. We often see it as elegant, attractive, with a smooth and shiny surface. It reflects brightness and holds a sense of purity. Over time, it has gained popularity in residences and commercial buildings. For functional and ornamental applications.

Durable – This metal is tough. It boasts high impact resistance. It does not buckle under immense weight. And can endure both extreme hot and cold temperatures.

Long Term Value –Looking at the facts. Stainless steel is recyclable, durable and has a low maintenance cost. This all translates to long term value. During any product made with stainless steel and its lifecycle.

Stainless steel is a wonderful choice. If you are looking for something clean, attractive, recyclable and durable.

So what exactly is the difference between galvanized steel vs stainless steel? Let’s look at some of the core differences below:

Prepare – The most common form of galvanizing steel is by a method known as hot-dipping. This is when we take a vat of molten zinc and dip the ordinary steel inside of it. Other methods are also possible. But the main point is that we coat galvanized steel on the surface with zinc.

For stainless steel, it isn’t coated. Instead we mix ordinary steel with chromium when both are in a molten state. Afterwards we allow the mixture to cool and harden. It then becomes stainless steel and after we examine for impurities.

Protection – When comparing the two for protective factors there actually is no competition. Galvanized steel is much weaker than stainless steel. This is because galvanized steel is only coated with a protective layer, being zinc. This coating wears away over time. So it does not provide protection from rusting for as long as stainless steel can. Since it we mix it with chromium to help prevent rust.

Cost – Galvanized steel is by far the cheapest metal of the two. Many take this into account when creating their next product.

Use – Galvanized steel has a weaker strength but a cheaper price. Because of this you would more likely find it used in smaller-budget projects. It also sees a lot of use in construction. From pipes and fittings across houses. When compared to other metals in general, many still find galvanized steel to be useful. From creating metal roofs to chain-link fencing. Since it is stronger and lighter than many other metals. Including rust-resistant and able to withstand harsh weathering.

The trade-off for stainless steel is that while it is more expensive it is also stronger. Much more so. Thus, for big-budget applications which need tougher components. Or heavy lifting or thicker components will find this metal useful. It finds use in the building of skyscrapers and bridges. But also cars, airplanes and many more large scale products.

You may decide to go with stainless steel or galvanized steel based on key factors. These include price, protection, preparation and your product.

Galvanized steel ranges across a wide range of applications. See some of these below:

Electronics – To help prevent rusting and moisture-free. It is common to make precision instruments and computer casings with this material.

Construction – Many applications use galvanized steel. Verandas, street furniture, support beams and staircases. To ladders, fences, handrails, industrial walkways and building frames.

Pipes – Galvanized pipes replace most lead and iron pipes. In cold water plumbing ever since the early 20th century. These pipes often maintain its integrity for up to 70 years.

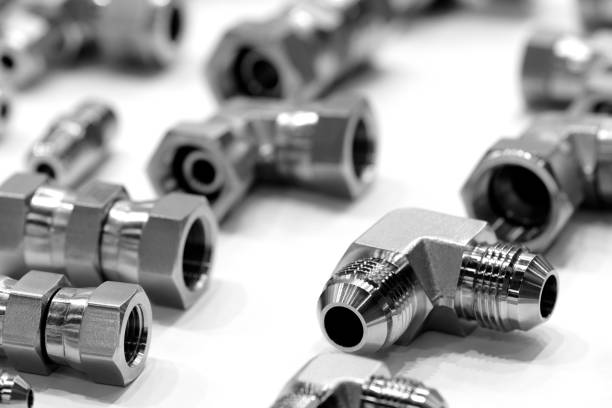

Bolts, Nails, Nuts – We use galvanized screws, galvanized bolts and galvanised nails. Why? These are all solid options to make them rust-proof.

Playground Equipment – Things like jungle gyms, swing sets and bike racks. All need to resist weathering and as such galvanizing these is a great option.

Transport – There is a large industry for galvanized steel. At least when it comes to planes and automotives. Used for spring housing, roofing, seating, brakes, oil pans, fenders and much more.

From transport to playground equipment. Galvanized steel is useful across a wide range of many industries.

Many industries opt for stainless steel as the material of choice in their products. Let’s take a look at some of the industries which stainless steel caters to:

Cutlery – Stainless steel provides a smooth and clean surface. This works great when using tactile products like cutlery. Spoons, forks and knives for example. Shiny surface textures and easy to clean. This makes stainless steel one of the most common choices in the industry.

Architecture – Stainless steel is tough and durable. With a low cost to maintenance. Because of these reasons it is often used in the construction of buildings. From roofing, cladding and facades in houses. Stainless steel even helps maintain the core structure of many buildings.

Medical – Hygiene is one of if not the most important factors in medical devices. Rusting must never be a factor for such delicate equipment. Stainless steel takes precedence for being an optimal choice in this regard.

Power Generation – An important characteristic with stainless steel is the ability to resist. Meaning resist corrosion in hot temperatures. It is a great choice for power generators used in ventilation shafts, gas and steam tribunes. It is even used in nuclear power plants.

Automotive – It too is in the automotive industry. Why? Because of low-impact to the environment, small life-cycle cost and low maintenance costs. Made for many parts of a vehicle. From the vehicle structure, to the exhaust, converter and many more.

Bridges – Stainless steel is a material that is low-cost but long-lasting. Making it an excellent candidate for constructing bridges.

From large-scale architecture to cars, planes and even rocket ships. Stainless steel is a powerful metal that is in many applications.

But do you want to cut to the chase and find out which is the best material of the two? Stainless steel vs galvanized steel, who wins? I’m sure you can figure it out already but that depends. It depends on the need of your next project and the kinds of properties you are looking for. Because as we have examined, they are very different from each other. While both types of steel have overlap on many different products and industries. One choice will always be preferable to the other.

For example, there will be some projects where stainless steel is not a viable option. While stainless is great in salt water it degrades if exposed to chlorinated water. It is also a bad choice when your stainless steel components create friction.

Galvanized steel also has its drawbacks. There are certain conditions in which the zinc coating can burn or fade away. Completely negating its protective properties. It also cannot last long against salt water exposure.

Are you still not sure which steel to use? You can always contact us here at Prototype Finder and we will assist you in the process.

In this post we took a look at galvanized steel vs stainless steel. First we looked at what both of these metals are. We explained how we here at Prototype Finder work with these materials. Checked out both of their advantages. But we also looked at the differences between them and the products they see common use in.

Do you need help from a professional manufacturer who can help create your next product? Then look no further. We at Prototype Finder can help you. We are one of the best injection molding and prototype manufacturing companies available. Having worked with both stainless steel and galvanized steel for many years. We are capable of producing your next project with both low or high volume production.

Will your next project include stainless steel or galvanized steel? Are you not confident which metal you want to use in your next product? Do you want help from trained professionals with many years of experience? Contact us or request a quote! Ask us any questions and we will be more than happy to help you in any way we can.

If you liked this post then make sure that you check out some other posts on many materials and topics. Check out our post on PVC vs HDPE. Or would you like to read about Aluminum Fabrication? Or is Overmolding is for you. Check them out.

Categories: BLOG

Tags:

Leave a Reply

Recent Posts

Comparative Analysis of Titanium and Aluminum in Manufacturing Blow Molding 101: What you Must Know Prototype Fabrication: The Critical Breakdown CNC 101: Everything you Need to Know about this Manufacturing Process Turning and Milling Stock: Everything you Must Know Overmolding: The Best Choice for your Next Product?Categories

Comparative Analysis of Titanium and Aluminum in Manufacturing Blow Molding 101: What you Must Know Prototype Fabrication: The Critical Breakdown 3D Printing Materials: 5 Ultimate Choices Overmolding: The Best Choice for your Next Product? Galvanized Steel vs Stainless Steel: Which is the Best MetalRelated Posts