●Injection Molding 50 to 50,000+ Parts

●Based in China with Low Cost

●Design For manufacturing for every project

●7 to 30 Days for Tooling & Molding

Plastic Injection Molding/Rapid Injection Mould

We provide rapid plastic injection mold tools and plastic injection molding parts. For a quick turnaround, we can use a “Master Unit Die”. Using this method means a very short lead-time. Also, the price is very competitive. Rapid tooling is a “bridge” between plastic prototypes and production injection molded parts. We are one of the few foreign-owned and plastic injection molding suppliers in China. We pride ourselves on our excellent communication and customer-focused mentality.

Projects often Get behind schedule due to design changes. If you need a quick solution, rapid tooling is the answer. Contact us for a quick quote today.

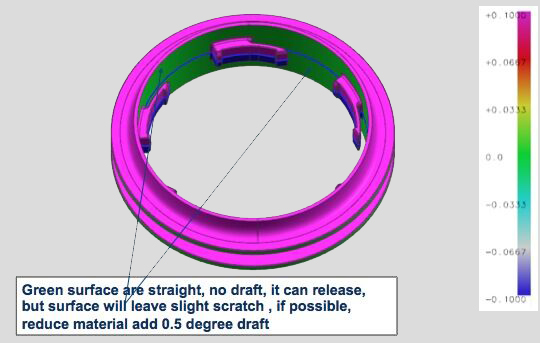

Design For Manufacturing

DFM (Design For Manufacturing) is essential to ensure a molded part is free from defects. DFM is the process of evaluation of a design being suitable for molding. If a part design has issues, we will help to provide a solution to solve the potential issues. Design issues can lead to sink marks, warping and other undesirable features.

There is no substitute for experience. Our experience has taught us to make molds in a “metal on” condition for critical areas. Once the DFM is complete the mold layout is confirmed. This includes position and type of gate, ejector pins position and parting line. We make a mold and aim for holes to be small and walls to be thin. We can adjust the sizes to create parts of the correct geometry. This way samples get to you, and on your desk in a matter of days.

Surface Texture

Textures on a plastic product give a part the appearance of sandblasting, wood, leather or others effect designed by customer. If you require your parts to be textured, please just send us the specification, like Mold-Tech texture standards. We can apply textures of all kinds normally used in plastic injection molding. For the rapid tooling, If you do not have specific requirement of your product appearance, we can apply direct sandblasting with different media size on the mold, this is a quick and cost effective way for rapid injection molds.

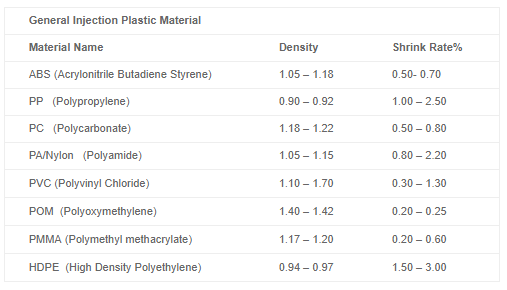

Plastic Material Selection

We can produce parts in most kinds of injection mold-able plastics including a wide selection of engineering plastics for high performance components and also all general plastic materials. We often import material if it’s not freely available in China. We can also provide 2 shot parts and over molded parts according to your needs. In addition to plastic parts, we also provide compression and injection molded rubber parts in a wide rage of materials including: EPDM, FKM, NBR, PU, Q, to name a few!

Rapid injection molding process or molded plastic products are widely applied in many industries, including most of commerical products, like home appliance industry, office accessories industry, electrical tools, auto industries and electronic devices.