1 Up to 100 or more parts

Polished & painted finishes

Parts shipped in as little as 3 days

Made in China to British standards

Rapid prototyping is a popular method of producing a realistic 3 dimensional model of a new design or a functional prototype. There are several processes used to produce a prototype, on this page we are just going to introduce two, 3D printing and vacuum casting.

Rapid Prototyping is a very popular way to produce a life like model that can be used for presentations and crowd-funding projects such as Kickstarter and Indigogo among many others. Having a visual model or functional prototype to show in your video is crucial in order to create a successful campaign.

We provide 3D printed prototype parts. We can provide models made from a variety of materials, including 3D printed metal and plastic prototypes. We can provide models made using SLA, SLS, FDM and DMLS processes. 3D printing is perfect for manufacturing very thin walled and small complex components. If speed is a critical factor, then 3D printing is the way to go. We can usually have 3D printed parts on your desk in 5 working days or less! Assemblies can be 3D printed, with thread inserts glued in place and buttons, displays, and circuit boards, fitted in order to create fully functional prototypes.

3D printing is taking off at an alarming rate! The hype surrounding the innovation that is taking place is incredible! It seems there are new machines coming on the market everyday, with features more exciting than the last, like built in laser scanners, built in milling capacity, and machines that really are portable. These machines are still aimed at the hobbyist or maybe designers, that just need a crude idea of how a design will look and feel. If you need a high quality 3D printed part, you still have to come to the professionals. Why not get a quote today? It’s free after all !

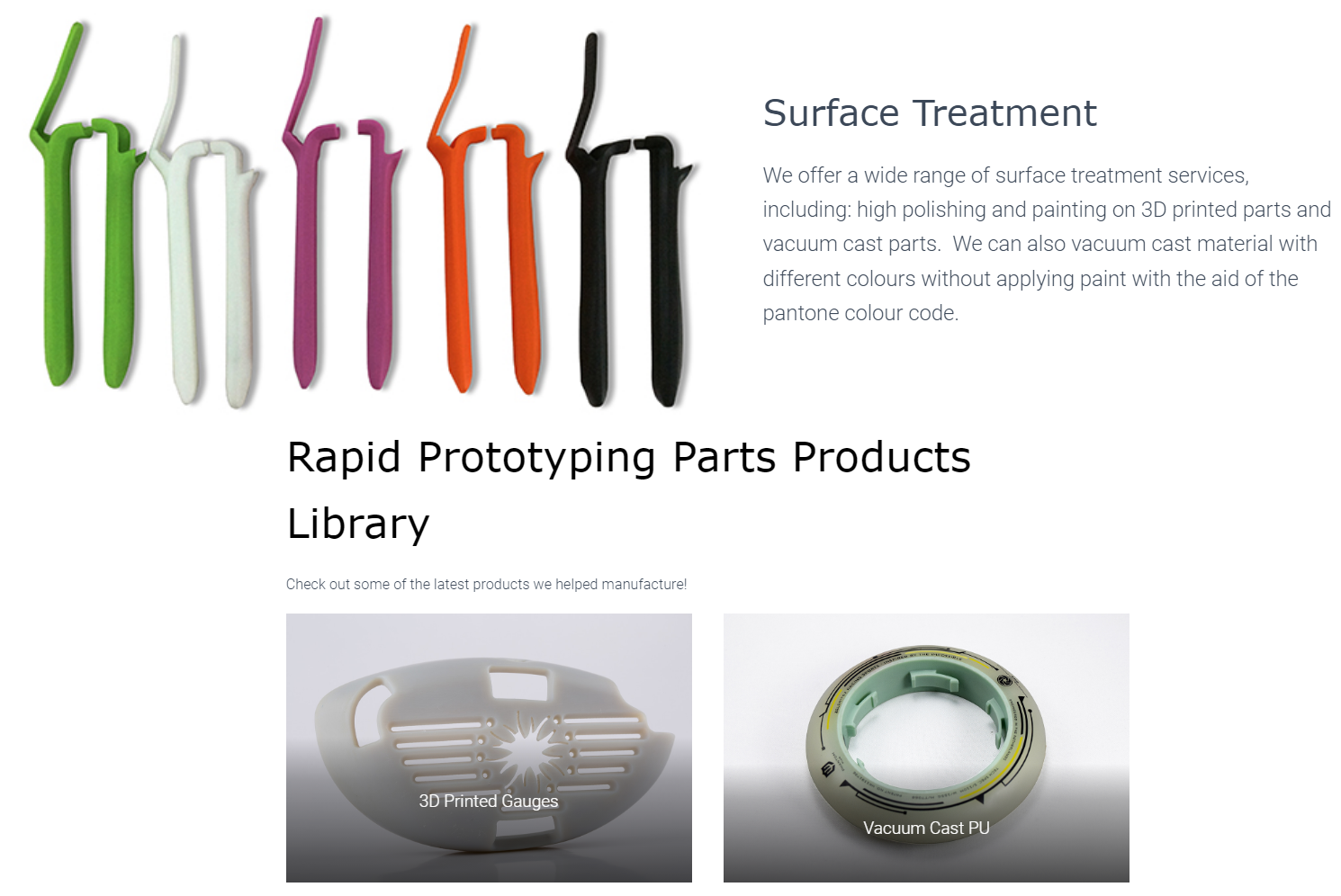

We provide vacuum cast parts also called urethanes casting process. This process is a great way to get a small batch of parts that are indistinguishable from injection molded parts. They can be self coloured and textured in the mold, just like real injection molded parts, but at a fraction of the cost. A range of materials are available, the most popular choice is simulated ABS. These parts can be over-molded with rubber effects. It is possible to mold in thread inserts or other inserts if required. This process is well suited to small batches, in most cases up to and around 100 parts. Accuracy and appearance of parts produced using this process is very good.

Vacuum cast parts are practically indistinguishable from injection molded parts. This process is the best option for batches of complex parts that have not yet been approved for production. Many millions of dollars have gone up in smoke because prototypes were not made first. Vacuum cast parts that are copies of a 3D printed parts which in turn are accurate representations of 3D CAD data, and are a sure fire way to make sure you have got it right before you sign the big tooling contracts. There are a wide range of materials available with different properties, if you would like to know more, please get in touch with us and get a quote today and see what peace of mind costs.