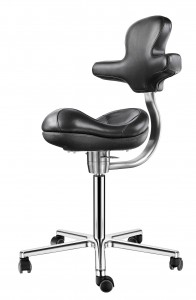

The core chair is a functional device with a saddle like seat covered with premium cow leather, and a unique shape of backrest also covered with premium cow leather. The back rest also has the function to rotate independently against the seat.

The designed unique mechanism is CNC machined from stainless steel 304 with a brushed finish. This chair is designed to help people to sit properly and reduce the back pain. This product is targeted to very high end markets. Processes: (Over 50 parts, 26 of them are customized components made from over 12 different manufacturing processes). Revolve Mechanism: CNC milling, CNC turning, EDM sparking, wire cutting, laser cutting, welding, bending, polishing, leaser engraving and assembly. Seats: Blow molding, copper inserts, memory foam manufacturing, leather cutting and stitching, gel pad molding, upholstery and assembly.

Backrest: Laser cutting, welding, expand foam molding, leather cutting and stitching, upholstery and assembly. Standard Components: PU/Nylon wheels, reinforced gas springs, NSK bearings, screws and washers. Material: Stainless steel 304, cow leather, expanding PU foam, memory foam, polypropylene, copper and aluminum. Lead-Time: 12 months. Quantity: 25 core chairs and 35 core stools.

David France, a chiropractor and the owner of Chaired Logic from Australia, devoted himself to develop the Core Chair and stool, to improve poor sitting posture and to reduce reoccurring back pain. Prototype Finder specializes in providing the total solution for big project with very small volume production. We provide varied manufacturing services and design services at a much lower cost compared to costs in western countries.