Welcome to our CNC machining service, where precision meets excellence!

At our core, we specialize in CNC machining, offering more than just prototypes or parts. Leveraging our engineering expertise and vast experience, we assist you in achieving your goals within budget and in record time. Thinking outside the box is our forte, and we actively explore cost-saving ideas to benefit you.

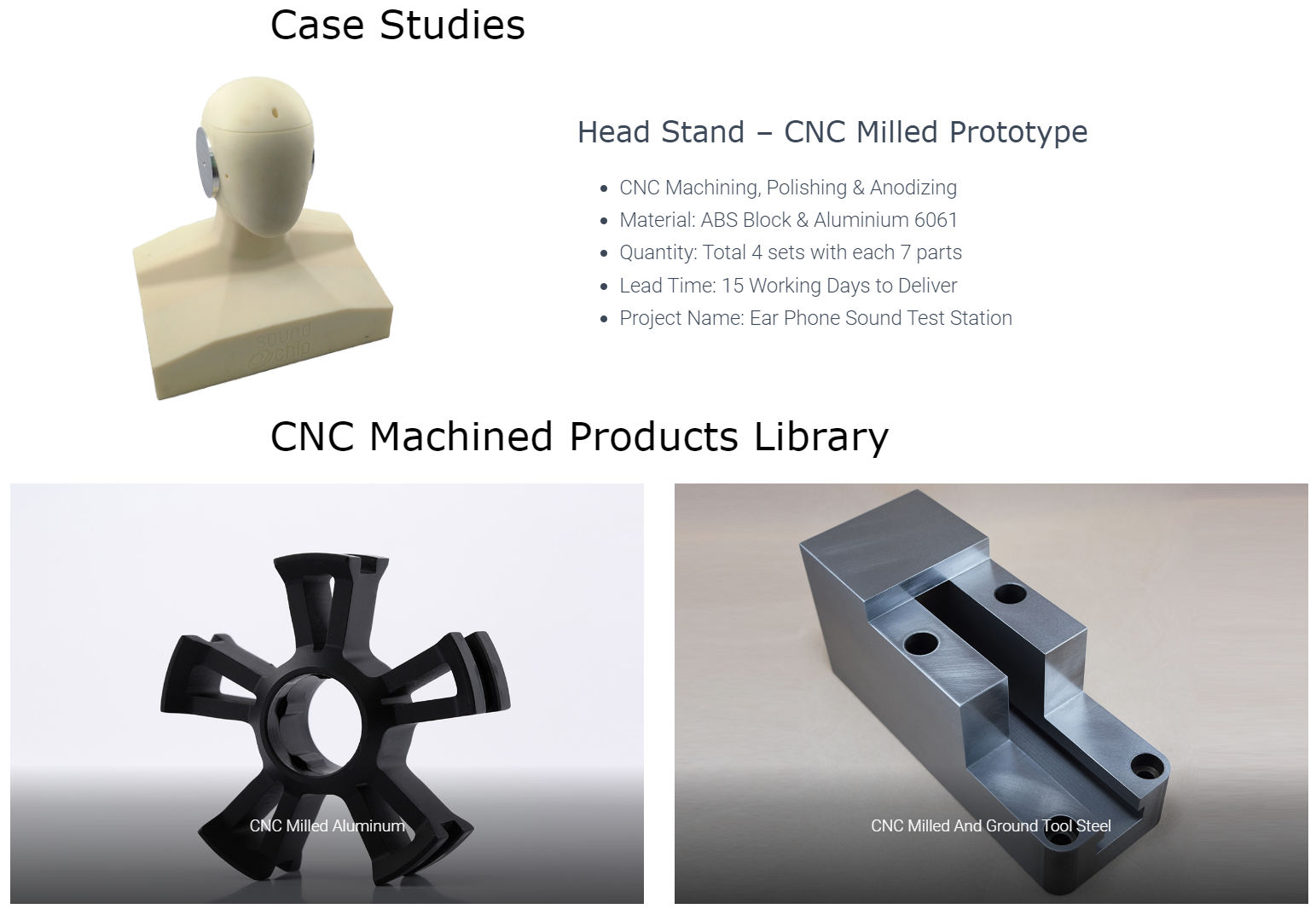

CNC Milling

We offer advanced 3, 4, and 5 Axis CNC milling services. Utilizing CNC machining provides a swift and cost-effective avenue for obtaining functional prototypes precisely tailored to your material and dimensional specifications.

Ensuring the consistency of parts is paramount, and we excel in this aspect through our proficiency in work holding. As specialists in fixture design and manufacturing, we prioritize quality without compromising cost efficiency. Our commitment extends to avoiding shortcuts that could compromise the integrity of your project.

If you require assistance in applying tolerances to guarantee a precision fit and consistent assembly, our team of engineers stands ready to support you. This service is seamlessly integrated into our comprehensive engineering support, ensuring that your components meet the highest standards.

Experience the precision and dedication that define our CNC machining services. Contact us to discuss how we can enhance your projects through meticulous craftsmanship, expert fixture design, and tailored engineering support.

CNC Turning

We specialize in producing small-diameter, precision-turned parts at scale, utilizing Swiss-style lathes and CNC turning machines. Our capabilities extend to crafting large, customized turned components such as rollers, shafts, flanges, etc., tailored for various industrial applications, including steel, aluminum alloy, titanium alloy, and plastics.

In addition to our turning expertise, we provide surface treatments for parts with lengths up to 3 meters, ensuring a comprehensive solution for your project needs. Backed by our managing director's extensive hands-on experience, we invite you to engage directly in discussions about the details of any turning or milling project. Your satisfaction is our priority, and we are committed to delivering precision and excellence in every aspect of our services.

Cylindrical Grinding

We possess robust capabilities and a proven track record in manufacturing a diverse range of steel shafts, rollers, and sleeves. Our expertise spans multiple materials, including hardened tool steel, mold steel, and chrome shafts. Over the years, we have successfully executed numerous projects involving punching and stamping molds, as well as components for paper manufacturing equipment. These projects cater to both local and overseas customers and involve a comprehensive array of manufacturing processes, such as cylindrical grinding, CNC milling, CNC turning, electro-discharge machining, hardening, electro-less nickel plating, drilling, tapping, honing, surface grinding, and rigorous 100% inspection protocols. Our commitment to excellence ensures that we deliver high-quality solutions tailored to the unique requirements of each project.

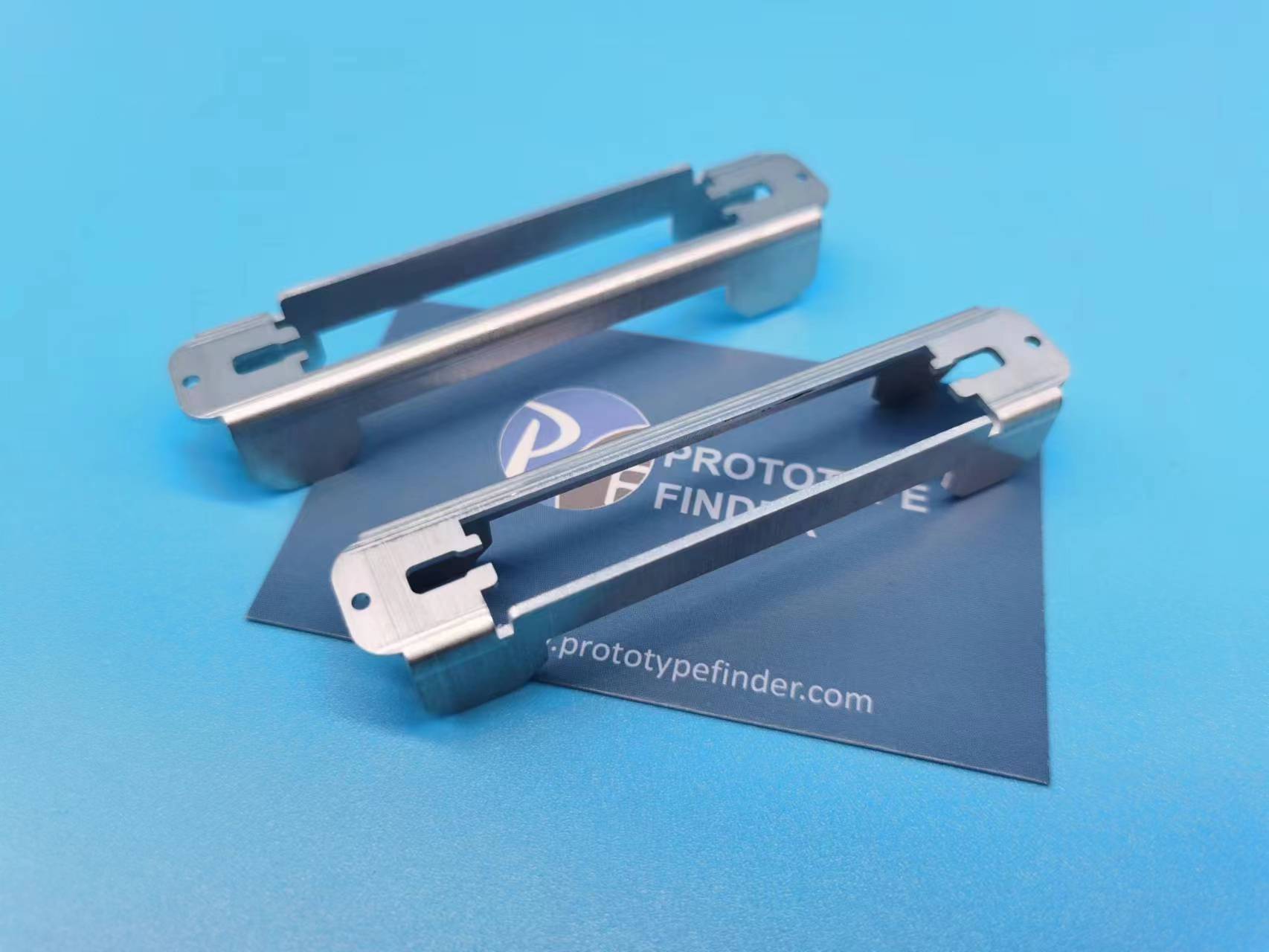

At Prototype Finder, customer satisfaction is our priority. Our team implements rigorous quality control procedures for both prototypes and production projects. For production quantities, we adhere to (PPAP), and for single prototypes, we conduct a 100% feature inspection. Our comprehensive quality assurance includes a first article approval procedure, a process control plan (PCP), and material testing for each batch.

We work with a variety of materials, including steel, stainless steel, tool and mold steel, carbon steel, titanium alloy, aluminum (Al 6061 and Al7075), and plastics like ABS, Nylon, PC, and PMMA. Our expertise extends to a wide range of surface treatments, adding a professional finish with options like electro-less nickel plating, chrome plating, anodizing, passivation, PVD, and heat treatments. Logos and text can be incorporated through engraving, laser etching, screen-printing, or pad printing.

Understanding that components may be designed with specific manufacturing processes in mind, we employ die sinking EDM and wire cutting EDM to overcome geometric restrictions, producing prototypes that truly represent the end product.

For inquiries or to discuss your project, feel free to contact us directly. Celebrate precision with Prototype Finder on our 10 year anniversary!